WASP – smooth sailing or hot air?

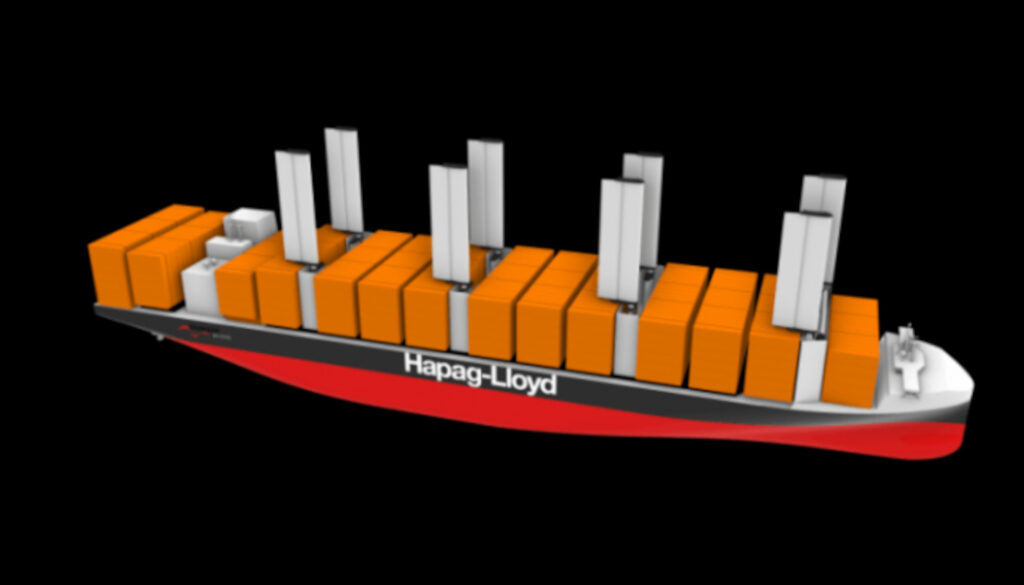

Sails are used on bulk carriers and tankers. The arrival of a new wind-powered container ship concept from Hapag-Lloyd provides an opportunity to discuss wind-assisted ship propulsion (WASP) in more detail, in this Q&A with Hapag-Lloyd in The Loadstar.

I hear there are new shipping companies using ‘tall ships’?

Indeed, there are. Sailcargo is one of them; it has a three-masted schooner, Vega, and another, Ceiba, is currently under construction. When finished, it will have a capacity of 250 tonnes of general cargo, the equivalent of nine teu.

However, hammering together clippers from oak planks is something of a lost art, which means Sailcargo and the handful of companies like Sailcargo will need a lot of help if they want to decarbonise shipping. In any case, we keep our fingers crossed for them.

So is this a return to the age of sailing?

Hardly. In the best possible circumstances, the best designs for existing sails can provide about 30 per cent of the propulsion needed to power a ship. That is certainly not to be sneezed at, but it is not a revolution either – nor is it a substitute for investment in other areas such as hull shapes and stud lubrication.

The advantage of sailing is highly situational. Close to the equator, the ‘trade winds’ blow from east to west and in the North Atlantic from west to east. There is a similar and potentially useful gyre in the Pacific: “west winds” (which, confusingly, blow east) across the North Pacific towards North America, and trade winds further south, blowing west, towards the (political) east.

However, there is a small problem: the sail is not the only thing propelling the ship. If a ship has to change its route to take full advantage of these drifts and gyres and burn extra fuel, it is the wrong economy.

But wind is free – surely sails are worthwhile for any ship?

Wind may be free, but modifying it is not. Many more ships could benefit from adding wind power than currently do, but ship owners can be quite stubborn when it comes to investing in new technologies, especially if their ships are more than a decade old.

And shipyards can also be pretty stuck-up. Never mind technologically advanced retractable sails, Foreship chief naval architect Markus Aarnio recently pointed out that many yards still do not even build the right shape of the hull. “Often, yards insist on optimising the hull shape only for test sail speed, even if that speed is rarely used in practice,” he says. However, the biggest barrier – and one that Hapag-Lloyd is trying to solve – is that not every ship is suitable for sailing.

Can modern technology help?

Absolutely. Amy Buhl, of WeatherNews (WNI), told The Loadstar that her organisation was in talks with shipowners about combining advanced weather forecasts – including WNI’s latest ‘probabilistic’ forecasts – with ships’ sails to create new, unprecedented efficiencies for ships. “It’s a really interesting conversation,” she says, “because it requires us to change how we think about voyage optimisation and how we can exploit weather conditions in this respect. I think we will see more of this as the technology becomes more widely adopted.”

Can container ships use sails?

Perhaps. But it is difficult without something getting in the way. Sails are high, but the stacks of containers will very quickly get in the way of the wind, which means that sails that we have seen so far are only used on flat-topped ships such as bulk carriers, tankers and ro-ros. Meanwhile, sails are being used on the quay.

Meanwhile, sails on the quay get in the way of rail cranes, meaning they have to make extra movements to reach the cargo. If sails on a container ship can reduce fuel consumption, this is immediately offset by more time (mostly fuel burn) on the quay.

Hapag-Lloyd’s design places a wall between the stacks of containers and although this protects the sails from loading-related accidents, it seems that cranes still have to move more to unload the same amount of cargo.

Then there is the issue of drift limitation. Becker Marine has recently developed a retractable sword system, similar to that on a sailboat. The underlying idea: sails create a force perpendicular to the direction of travel, something that engine-driven ships are not necessarily designed to handle. But if ships have a sail pulling on them from higher up, they also need something below the waterline, Becker MD Dirk Lehmann reasoned. “If the ship has a certain deviation, it produces lift to the correcting side, like the daggerboard on a sailboat,” he explained at the SMM in Hamburg last year.

If Mr Lehmann is right and corresponding underwater accessories are needed to support the sails on top, it will be interesting to see how Hapag-Lloyd’s plan to place them well above the ship’s centre of mass will pan out.

You don’t seem very sure about all this?

The weather is uncertain – it is the main reason why we stopped using wind. And it is only likely to get more uncertain, according to Ms Buhl. “…the effects of global warming are not observed evenly… some areas are more affected than others, which means that temperature differences are getting bigger.”

And recently, she said, “…we are seeing…a rapid intensification of tropical cyclones – tropical systems that rapidly increase in wind speed in short time intervals. We are also seeing more ‘bombing lows’ – a similar type of dynamic for a mid-latitude system, where the low rapidly deepens over a short period of time.”

Read the entire article on The Loadstar website.